Torque Advice For PV Installers – One Grunt Or Two Grunts?

by Brian Mehalic – SEIPS Senior Technician

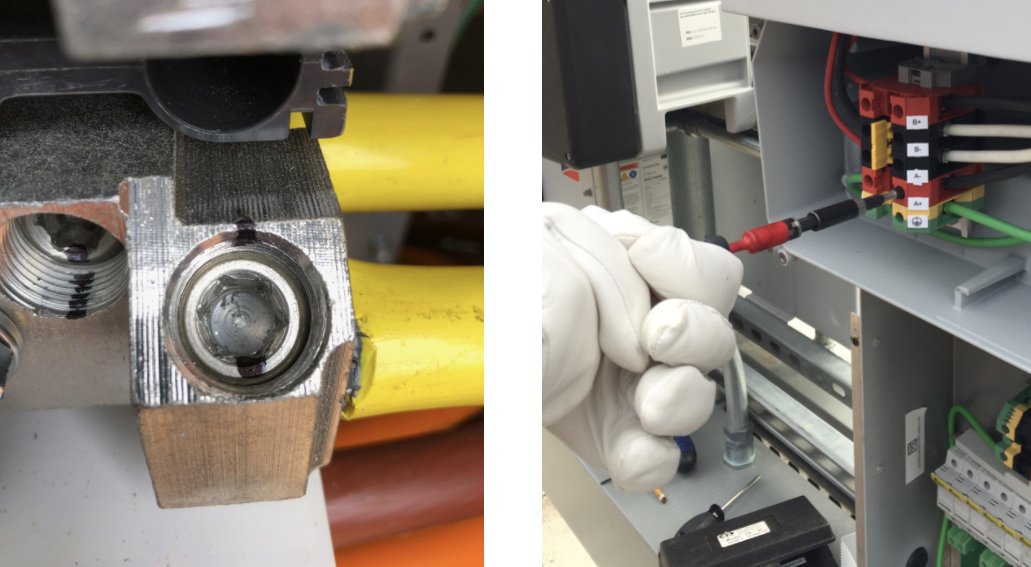

I inspect a lot of PV systems, and the most common problem I see is electrical connections not being properly tightened. This is by no means a PV-specific problem, attested to by the addition of Section 110.14(D) in the 2017 National Electrical Code. I’m paraphrasing here, but basically if the equipment specifies a torque value, you have to use a calibrated torque tool to ensure proper tightness (unless the manufacturer provides an alternative – such as swage connections or the turn-of-nut method).

The problems associated with loose connections – increased resistance, overheating, and possible catastrophic meltdown – are well known, and are exacerbated in the extreme environments that PV system equipment is often exposed to. At the very least, lost production and difficult troubleshooting are the result. Existing loose connections may be found with an O&M plan that includes thermal imaging of terminations and/or torque check verification. But of course, it’s best to do it right during the installation.

Many veteran electricians and PV installers were not trained to use torque tools (one grunt = tight, two = very tight), and unfortunately many don’t even own one, let alone a tool that has been maintained and calibrated per the manufacturer’s specifications. This has to – and is – changing. Sometimes slowly, when I find it during my inspections, point it out, and have the installers go back and torque everything; and sometimes more rapidly when companies realize the importance of proper torque and train their crews appropriately.

Of course, using a calibrated torque tool can prevent other problems too – Along with wire damage, overtightening a termination on a printed circuit board may cause costly damage to the component.

And don’t forget to mark your properly-torqued connections: paint is far superior to sharpies!

Brian Mehalic – Senior Technician

Brian Mehalic is a founder of SEIPS and SEIE, and is a NABCEP Certified PV Installation Professional™ with over 13 years of experience designing, installing, inspecting, and maintaining all types and sizes of systems, ranging from off-grid in the Amazon to commercial rooftop PV and multi-megawatt utility-scale. He is also a frequent contributor to SolarPro and Home Power magazines and an Instructor for Solar Energy International (SEI).

Contact SEI Professional Services (SEIPS) Today!

SEI Professional Services (SEIPS) leverages decades of experience in the solar industry to take your solar project from concept to reality. No matter what stage you are currently at in your solar project planning or construction – we are here to serve you. SEIPS can assist you as an industry leading solar energy consulting company to ensure your project gets completed on time and within budget for years of reliable clean energy production.

SEIPS provides expert services during every stage of the project development cycle from concept to commissioning and beyond through operations and maintenance (O&M) services. Contact us today and one of our technical specialists will work with you to maximize your solar project. Contact Jeff Ruppert PE, Business Manager / Civil Engineer for SEI Professional Services / SEI Engineering @ (970) 948-5744 or jeff@seisolarpros.bowman.com.